M Series machine with very high position and repetition accuracy for medium and large-sized parts

Machines are designed and analyzed with 3-D computer programs, manufactured as welded steel construction, “stress relieved”, precisely machined in moving column CNC machining centers, equipped with world-known parts and presented to the customers use after many stages of quality control processes.

- Worldwide, the most extensive database, which can be simply expanded with additional material characteristics and parameters

- The only machine that doesn’t produce angle errors. It offers the highest repetition accuracy on the market

- First class bending results thanks to pressure reference technology with fully automatic, dynamic crowning

- The wide range of equipment packages guarantee a customer-specific and flexible machine specification

- At the press of a single button, perfect bending results are achieved independent of operator knowledge

Standard Features

- Y1, Y2, X, R CNC 4 Axes (X + R Servo)

- 410 mm Stroke, 410 mm Throat Depth

- ESA S650 CNC Control Unit

- ±0,01 accuracy SERVO motorized back gauge. X=750 mm

- CAD sistem for bending programme development

- Quick clamp Promecam punch tool holder

- Tool and bend equipment cabinet

- Sliding front sheet support arms with hand Wheel

- Motorized Anti-deflection crowning with original Wila wedges

- CNC crowning compensation system

- MVD special narrow bottom table (European type)

- GIVI optic linear scales

- Standard punch tools (H: 67, 85°, R:08)

- Standard die tools (60x60 mm, 4 Vee V=16-22-35-50 mm, 85°, H:60)

- LED illumination on RAM

- Voltage: 400/480V, 50/60Hz, 3Ph

Optional features

- X to 2-4-6-8 axis back gauge options

- Wide bottom table for Multi Vee dies

- Anti-deflection crowning with original Wila wedges

- AKAS or DSP front laser safety systems

- Additional back gauge fingers

- Front laser safety

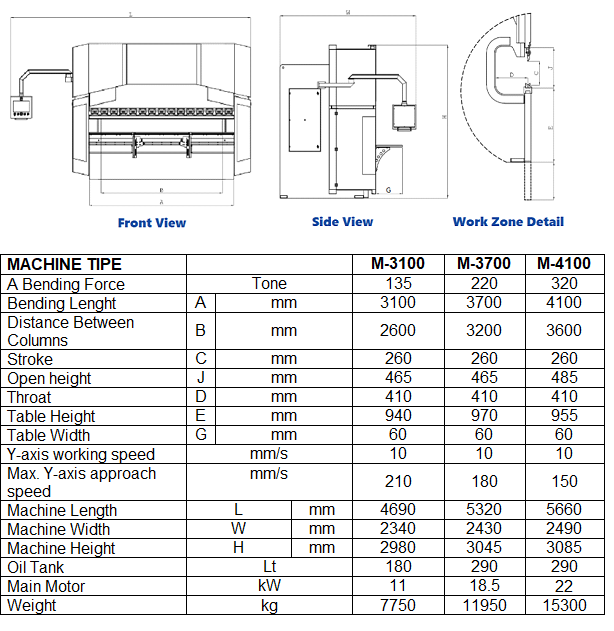

Technicial specifications

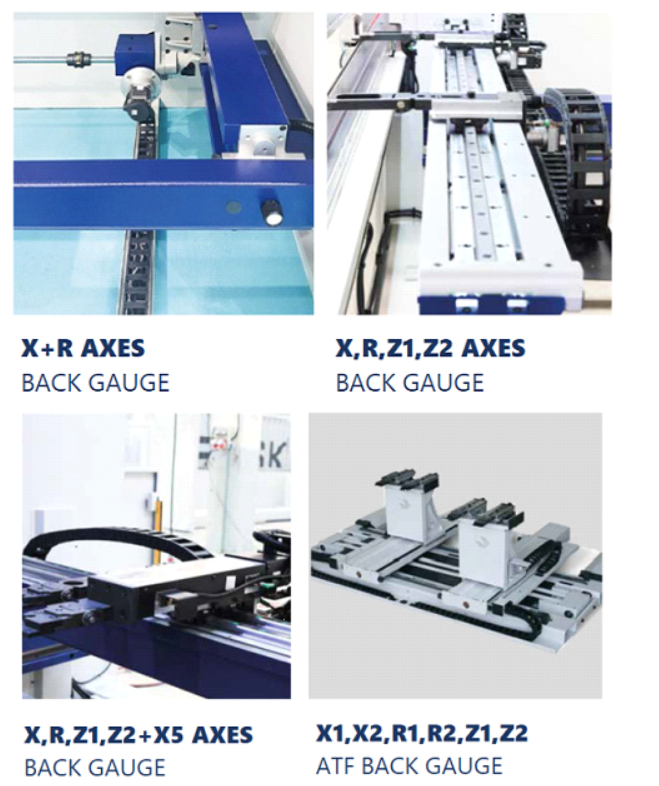

Back gauge options

- High speed

- Strong structure

- Linear scales

- Ball bearing system without backlash

- 3 step fingers with micrometric adjustment

- Robust design againts hard impacts

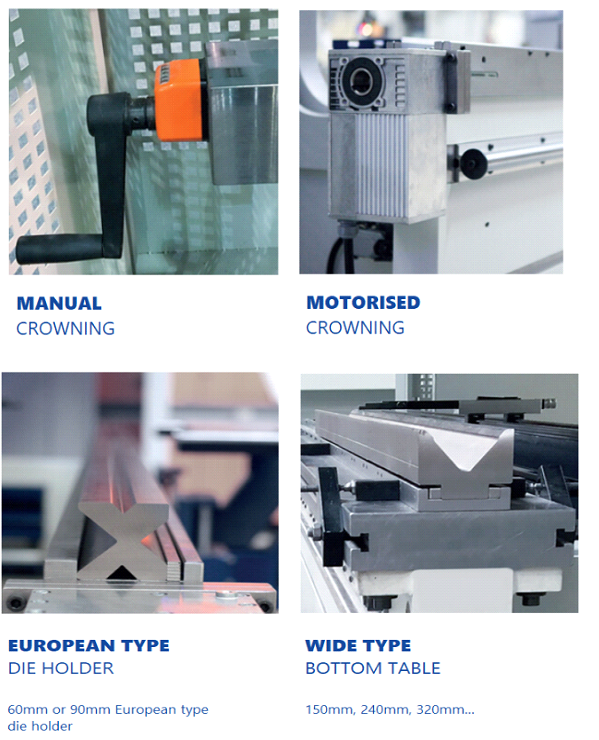

Top tool clampings

- Easy tool changing

- Fast

- Vertical tool changing

- Safe tool changing

- Options for different needs

- Strong and durable

Crowning & bottom tool clampings

Other options