S Series compact speed machine for small and medium-sized parts

- Maximum process speed via high acceleration of the upper beam and back gauge

- Ideal when there’s a shortage of space and capacities fluctuate: The machine can be operational or mobile in less than five minutes

- Process controlled reduces electric power consumption by up to 30 percent and decreases wear

- High ease of use through ergonomic design and individual customizable work environment

Standard Features

- Y1, Y2, X CNC 3 Axes

- 260 mm Stroke, 410 mm Throat Depth

- ESA S630 CNC Control Unit

- CAD sistem for bending programme development

- Manual Promecam punch tool holder

- MVD special narrow bottom table (European type)

- Standard punch tools (H: 67, 85°, R:08)

- Standard die tools (60x60 mm, 4 Vee V=16-22-35-50 mm, 85°, H:60)

- Tool and bend equipment cabinet

- High quality and precision linear scales

- LED illumination on RAM

- Voltage: 400/480V, 50/60Hz, 3Ph

Optional features

- R axis back gauge

- Sliding front sheet support arms

- Wide bottom table for Multi Vee dies.

- Anti-deflection crowning with original Wila wedges

- AKAS or DSP front laser safety systems

- Additional back gauge fingers

- Front laser safety

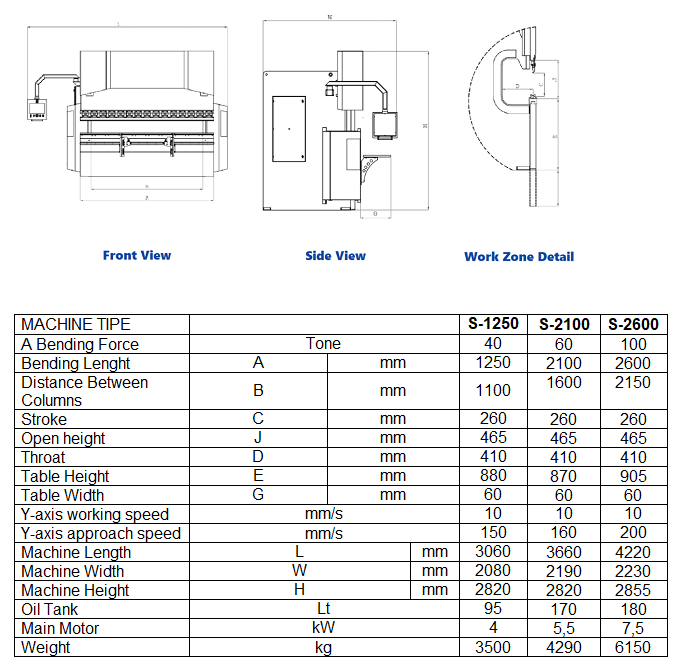

Technicial specifications

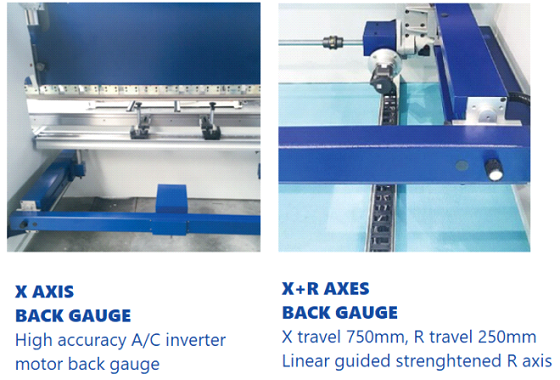

Back gauge options

- High speed

- Strong structure

- Linear scales

- Ball bearing system without backlash

- 3 step fingers with micrometric adjustment

- Robust design againts hard impacts

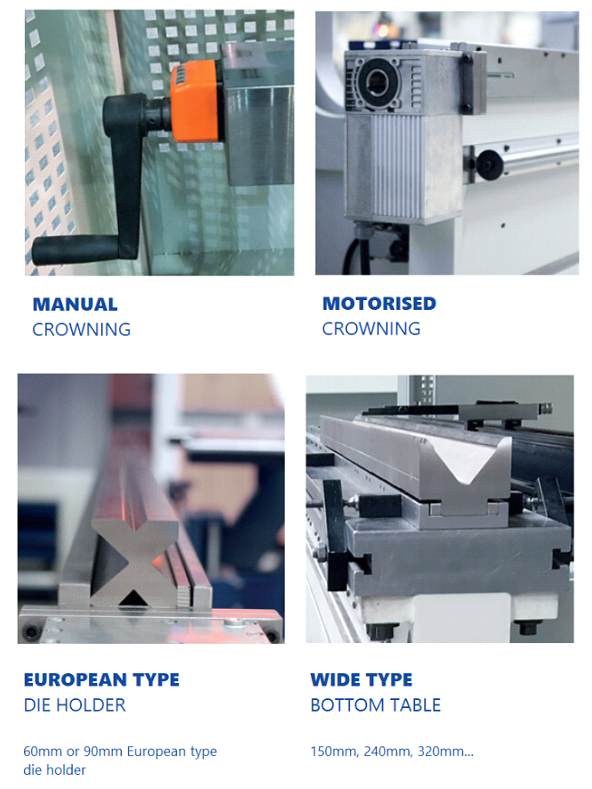

Top tool clampings

- Easy tool changing

- Fast

- Vertical tool changing

- Safe tool changing

- Options for different needs

- Strong and durable

Crowning & bottom tool clampings

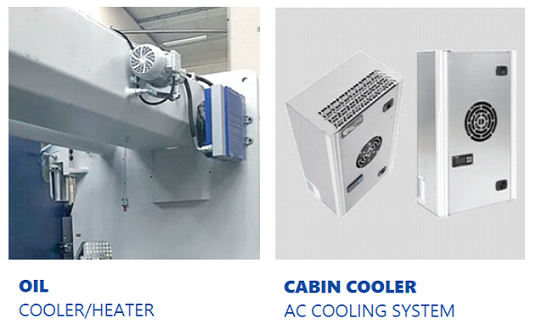

Other options